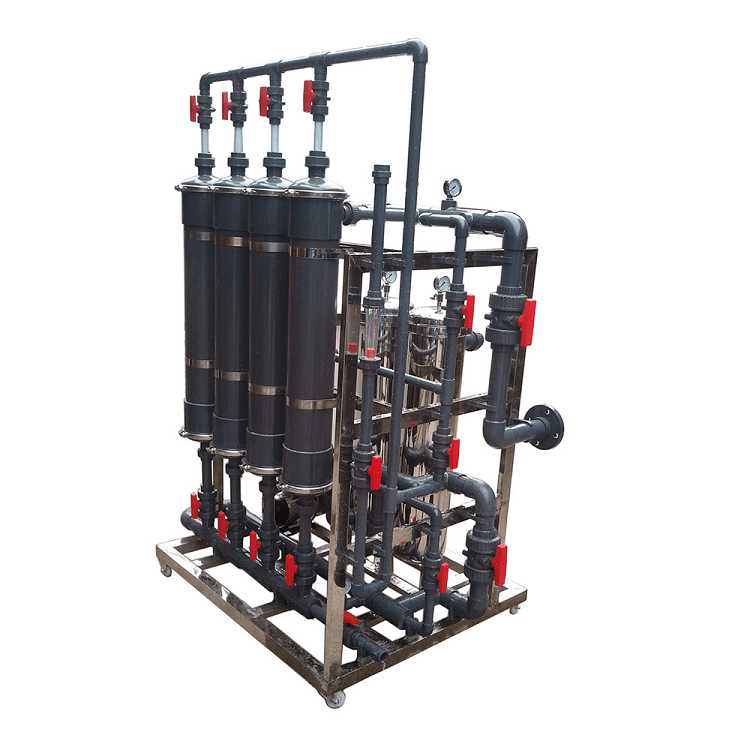

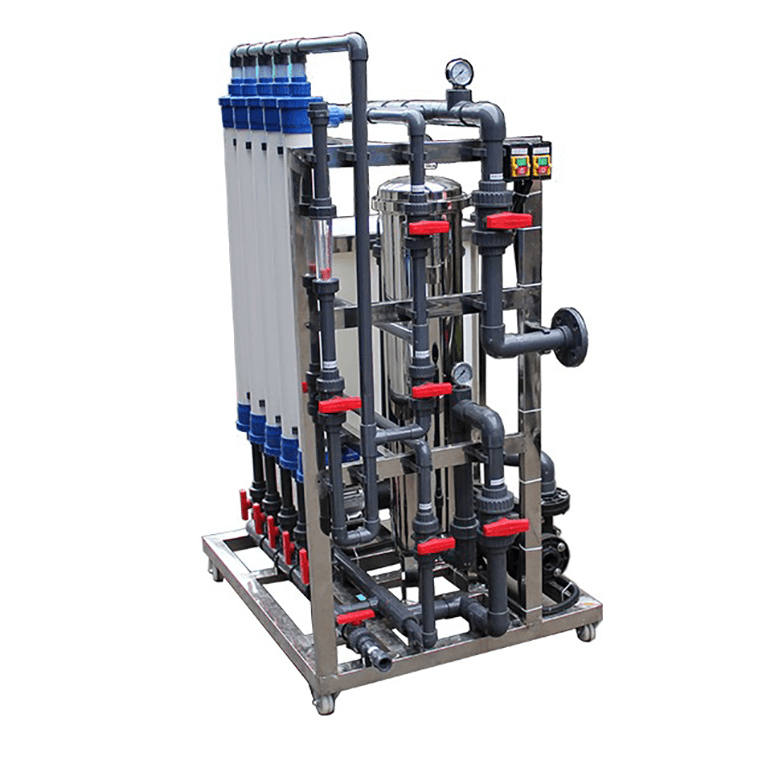

To meet the needs of closed cycle leaching recovery of electrophoretic paint, removal of impurity ions, purification of bath solution, improve coating quality.

Capacity: According to client requirement customized.

Electrophoresis painting UF System, to meet the needs of closed cycle leaching recovery of electrophoretic paint. The electrophoretic paint recovery rate can be more than 98%, which can be used to clean the electrophoretic paint, which can be applied to the coated product. If you do not use the ultrafiltration system, the recovery rate is only 70%-80%.

Electrophoretic painting, also called electrophoretic deposition of paint, electrodeposition painting, or E-coating, is an economical and corrosion-resistant technique for applying coatings to electrically conducting materials. It is widely used to coat many industrial products such as automobile bodies and parts, tractors and heavy equipment, metal furniture, and beverage containers. The process is carried out with the use of anodes and cathodes in the painting tank. There are two types of electrophoretic painting: anaphoretic and cataphoretic painting. In anaphoretic painting the profiles will be the anode, and in cataphoretic painting the profiles will be the cathode. In the electrophoretic painting process, evolution of oxygen gas will take place at the anode, and hydrogen gas will be evolved at the cathode.

The electrophoretic paint is continuously circulated to avoid settling of the paint solids and heat resulting from the pumping process as well as from the passage of electric, the treatment process as below: